| Availability: | |

|---|---|

| Quantity: | |

130 Series

Ritscher international Limited

The 130 Series is a high-performance, compact frame AC servo motor system engineered explicitly for the precision motion demands of industrial coating machinery. Operating on a 380V three-phase AC supply, this motor-drive combination delivers exceptional dynamic response, positioning accuracy, and torque stability, which are critical for achieving uniform film thickness, consistent quality, and high throughput in modern coating processes.

Precision Engineered for Coating Processes: Optimized for smooth, low-speed operation and high torque rigidity to eliminate velocity fluctuations that cause streaks, orange peel, or uneven coating layers. Enables precise synchronization of web tension, roller speed, and applicator head movement.

High Dynamic Response & Stiffness: Features a high torque-to-inertia ratio for rapid acceleration/deceleration, allowing for fast production line speeds and precise start-stop cycles at coating boundaries or during pattern changes. High loop gain ensures minimal deviation under sudden load changes.

Ultra-High Efficiency & Thermal Management: Utilizes advanced electromagnetic design and low-loss materials to maximize power conversion efficiency, reducing energy costs and heat generation. This allows for continuous duty operation in temperature-controlled environments without derating.

Absolute Positioning Accuracy: Integrated high-resolution encoder (e.g., 20-bit or higher) provides absolute position feedback, enabling repeatable precision for tasks like synchronized rotary screen indexing, precise valve control, or repetitive transverse carriage movement.

Robust Construction for Industrial Environments: Housed in a rugged, IP65-rated enclosure (dust-tight and protected against water jets) to withstand exposure to solvents, particulates, and humidity common in coating rooms. Corrosion-resistant treatments are available.

Seamless System Integration: Fully compatible with the matching 130 Series servo drive, supporting industry-standard fieldbus protocols (EtherCAT, PROFINET, Modbus TCP/IP, CANopen) for easy integration into centralized machine control systems and recipe management.

Low Vibration & Audible Noise: Precision manufacturing and balancing ensure exceptionally smooth rotation, which is vital for maintaining a stable meniscus in precision applicators and for operator comfort.

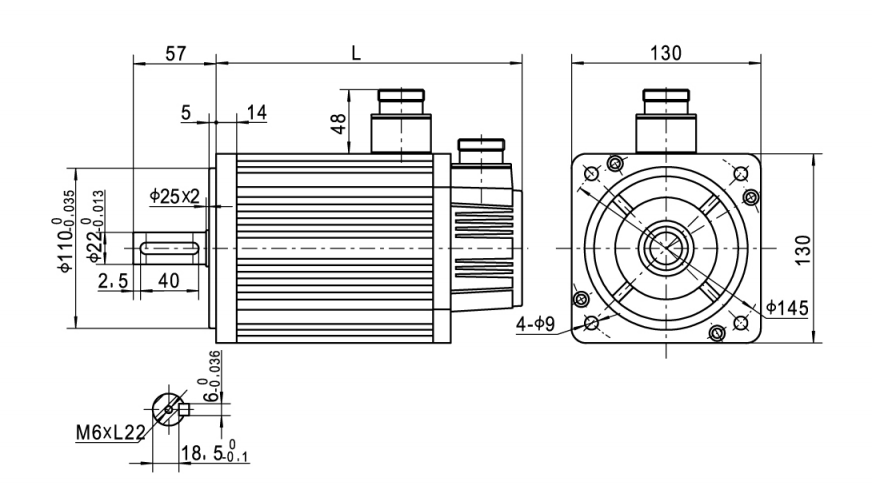

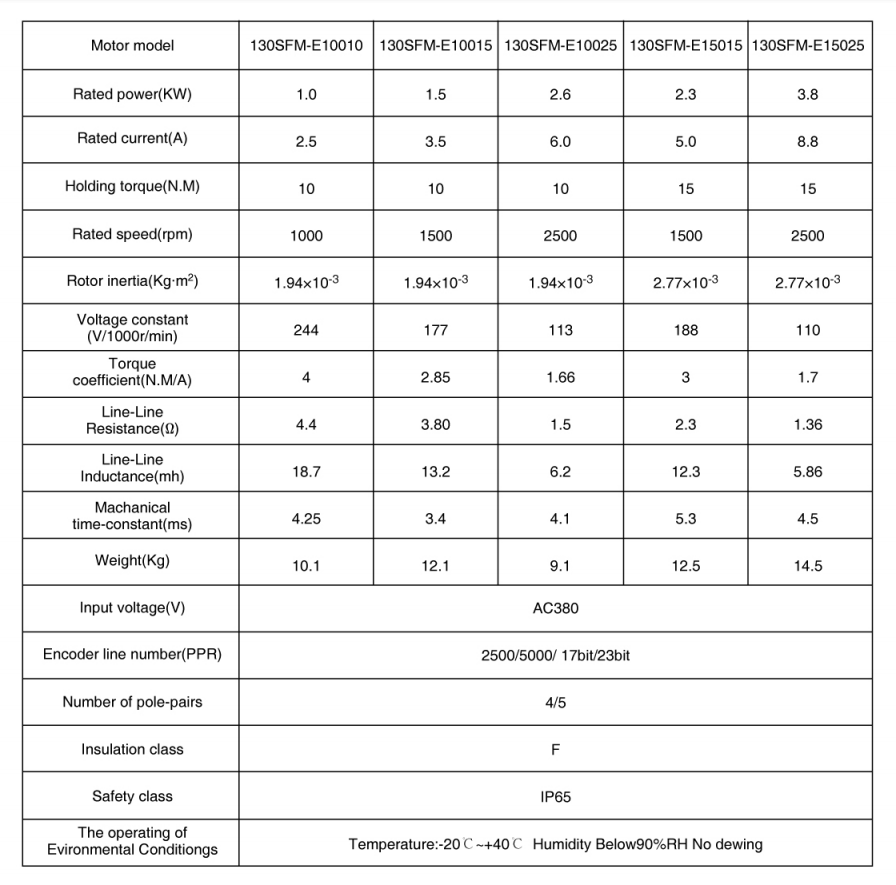

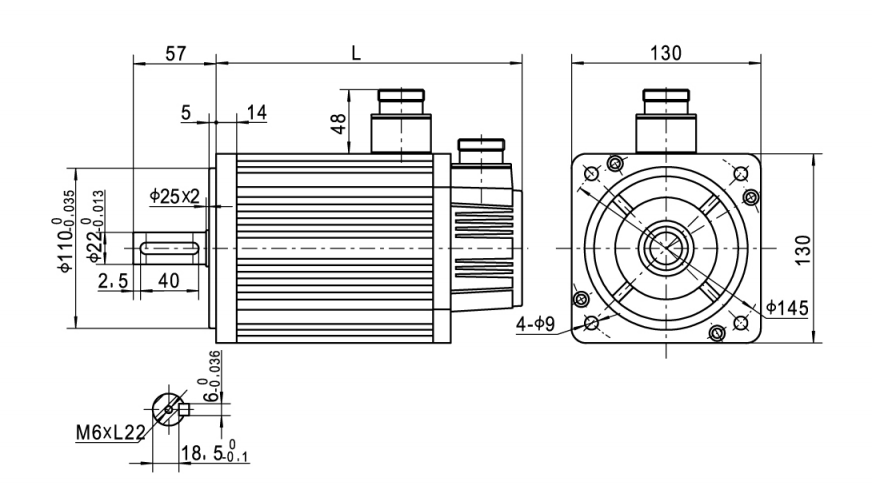

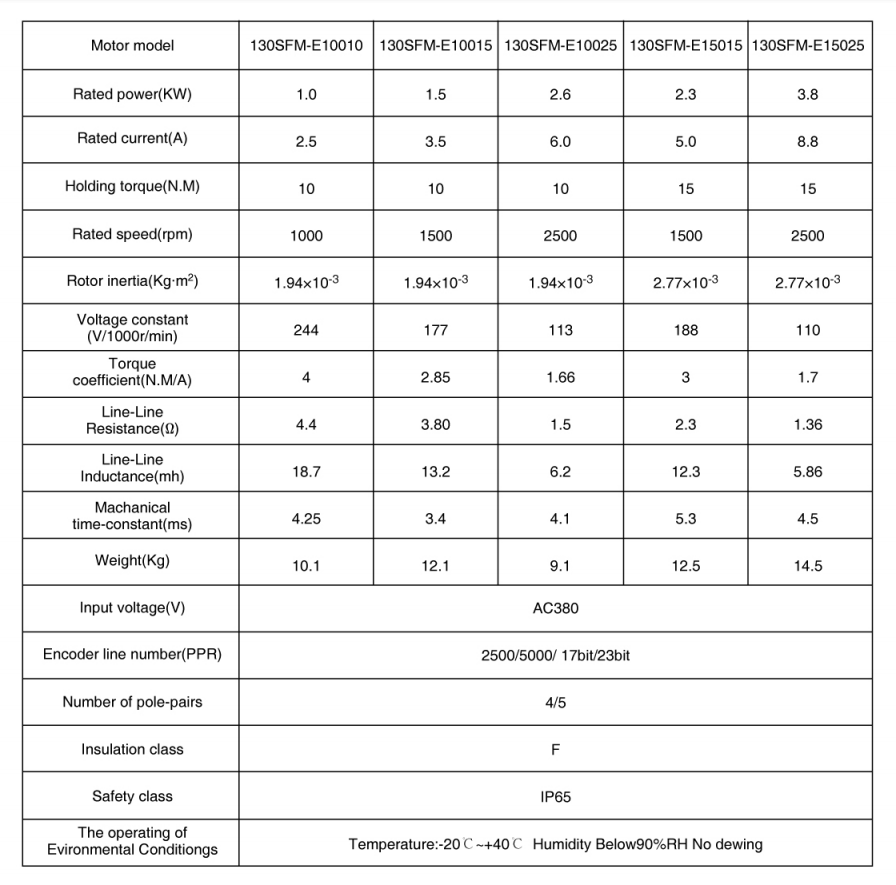

Frame Size: 130mm square flange.

Power Supply: 3-Phase AC 380V (±15%), 50/60 Hz.

Power Range: Typically from 0.4 kW to 3.0 kW.

Rated Speed: Commonly 1500 RPM or 2000 RPM, with a wide constant torque range.

Feedback Device: Multi-turn absolute encoder standard. Optional high-resolution incremental encoder.

Protection Class: IP65 standard (shaft seal included). IP67 optional.

Insulation Class: Class F (155°C) with Class B (130°C) temperature rise, equipped with thermal sensors (PTC/KTY).

Cooling Method: Natural convection (IC410) or through external cooling.

Certifications: CE, RoHS compliant. Designed to meet relevant parts of IEC 61800 and IEC 60034 standards.

Web Handling: Provides precise speed and tension control for unwinding, coating, and rewinding of flexible substrates (film, foil, fabric, paper).

Roller Drives: Ensures perfectly synchronized speeds between applicator, metering, and backing rollers for precise coat-weight control.

Reciprocating Systems: Drives spray guns, slot dies, or extrusion heads with precise linear or oscillating motion for uniform cross-web distribution.

Rotary Atomizers: Delivers stable, high-speed rotation for spindle-driven coating heads.

Precision Roll Coaters & Laminators

Extrusion Coating & Casting Lines

Spray Coating & Powder Coating Machines

Slot Die Coaters and Curtain Coaters

Printing Presses with Coating Units

Photovoltaic & Battery Electrode Coating Equipment

For coating machine OEMs and integrators, process consistency directly determines product quality and material yield. The 130 Series Servo Motor provides the foundational motion control precision necessary to eliminate defects and minimize waste. Its combination of dynamic performance, ruggedness, and seamless controllability translates into higher line speeds, faster recipe changeovers, and superior coating uniformity—making it a critical investment for achieving a competitive edge in precision manufacturing.

Note: Optimal system performance requires pairing with the corresponding servo drive and proper tuning for the specific mechanical load. Consult the detailed technical manual for torque-speed curves, inertia matching guidelines, and recommended mounting practices

The 130 Series is a high-performance, compact frame AC servo motor system engineered explicitly for the precision motion demands of industrial coating machinery. Operating on a 380V three-phase AC supply, this motor-drive combination delivers exceptional dynamic response, positioning accuracy, and torque stability, which are critical for achieving uniform film thickness, consistent quality, and high throughput in modern coating processes.

Precision Engineered for Coating Processes: Optimized for smooth, low-speed operation and high torque rigidity to eliminate velocity fluctuations that cause streaks, orange peel, or uneven coating layers. Enables precise synchronization of web tension, roller speed, and applicator head movement.

High Dynamic Response & Stiffness: Features a high torque-to-inertia ratio for rapid acceleration/deceleration, allowing for fast production line speeds and precise start-stop cycles at coating boundaries or during pattern changes. High loop gain ensures minimal deviation under sudden load changes.

Ultra-High Efficiency & Thermal Management: Utilizes advanced electromagnetic design and low-loss materials to maximize power conversion efficiency, reducing energy costs and heat generation. This allows for continuous duty operation in temperature-controlled environments without derating.

Absolute Positioning Accuracy: Integrated high-resolution encoder (e.g., 20-bit or higher) provides absolute position feedback, enabling repeatable precision for tasks like synchronized rotary screen indexing, precise valve control, or repetitive transverse carriage movement.

Robust Construction for Industrial Environments: Housed in a rugged, IP65-rated enclosure (dust-tight and protected against water jets) to withstand exposure to solvents, particulates, and humidity common in coating rooms. Corrosion-resistant treatments are available.

Seamless System Integration: Fully compatible with the matching 130 Series servo drive, supporting industry-standard fieldbus protocols (EtherCAT, PROFINET, Modbus TCP/IP, CANopen) for easy integration into centralized machine control systems and recipe management.

Low Vibration & Audible Noise: Precision manufacturing and balancing ensure exceptionally smooth rotation, which is vital for maintaining a stable meniscus in precision applicators and for operator comfort.

Frame Size: 130mm square flange.

Power Supply: 3-Phase AC 380V (±15%), 50/60 Hz.

Power Range: Typically from 0.4 kW to 3.0 kW.

Rated Speed: Commonly 1500 RPM or 2000 RPM, with a wide constant torque range.

Feedback Device: Multi-turn absolute encoder standard. Optional high-resolution incremental encoder.

Protection Class: IP65 standard (shaft seal included). IP67 optional.

Insulation Class: Class F (155°C) with Class B (130°C) temperature rise, equipped with thermal sensors (PTC/KTY).

Cooling Method: Natural convection (IC410) or through external cooling.

Certifications: CE, RoHS compliant. Designed to meet relevant parts of IEC 61800 and IEC 60034 standards.

Web Handling: Provides precise speed and tension control for unwinding, coating, and rewinding of flexible substrates (film, foil, fabric, paper).

Roller Drives: Ensures perfectly synchronized speeds between applicator, metering, and backing rollers for precise coat-weight control.

Reciprocating Systems: Drives spray guns, slot dies, or extrusion heads with precise linear or oscillating motion for uniform cross-web distribution.

Rotary Atomizers: Delivers stable, high-speed rotation for spindle-driven coating heads.

Precision Roll Coaters & Laminators

Extrusion Coating & Casting Lines

Spray Coating & Powder Coating Machines

Slot Die Coaters and Curtain Coaters

Printing Presses with Coating Units

Photovoltaic & Battery Electrode Coating Equipment

For coating machine OEMs and integrators, process consistency directly determines product quality and material yield. The 130 Series Servo Motor provides the foundational motion control precision necessary to eliminate defects and minimize waste. Its combination of dynamic performance, ruggedness, and seamless controllability translates into higher line speeds, faster recipe changeovers, and superior coating uniformity—making it a critical investment for achieving a competitive edge in precision manufacturing.

Note: Optimal system performance requires pairing with the corresponding servo drive and proper tuning for the specific mechanical load. Consult the detailed technical manual for torque-speed curves, inertia matching guidelines, and recommended mounting practices