| Availability: | |

|---|---|

| Quantity: | |

80 series

Ritscher

The Ritscher 80 Series is a high-efficiency AC servo motor designed specifically for industrial automation and motion control applications. With a compact 80 mm flange, 220 V three-phase power, and peak torque up to 48 Nm, this motor delivers exceptional performance for demanding environments. Equipped with a 17-bit absolute encoder and supporting EtherCAT, CANopen and Modbus communication protocols, the 80 Series ensures precise positioning, fast response, and seamless integration.

High Efficiency (IE4/IE5 level) — Optimised rotor design and low-loss winding reduce energy consumption and heat generation.

Wide Torque & Speed Range — From 0.6 Nm up to 48 Nm, speeds from 500 to 6000 RPM.

220 V 3-Phase Supply — Standard European/Asian industrial voltage for general-purpose installations.

17-bit Absolute Encoder (Standard) — Provides high-resolution feedback, eliminates homing cycle, supports multi-turn options.

Robust Protection & Compact Design — IP65 rated (IP67 optional), vibration resistance, NEMA34/42 compatible mounting.

Multi-Protocol Support — EtherCAT, CANopen, Modbus; Compatible with major drives (Yaskawa, Siemens, Delta, etc.).

Customisable Options — Brake, special shaft/coating, custom cable length, leading OEM/ODM support.

Industry Ready — Ideal for servo presses, CNC machines, robotic arms, labelling machines, pick-and-place equipment and other high-precision systems.

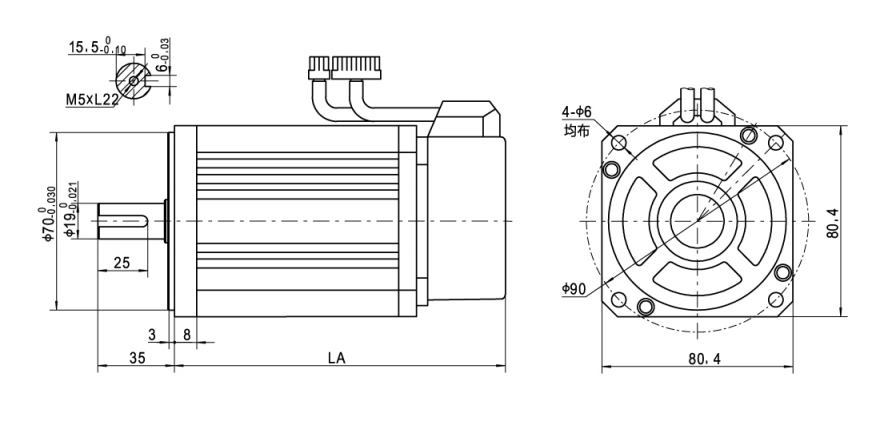

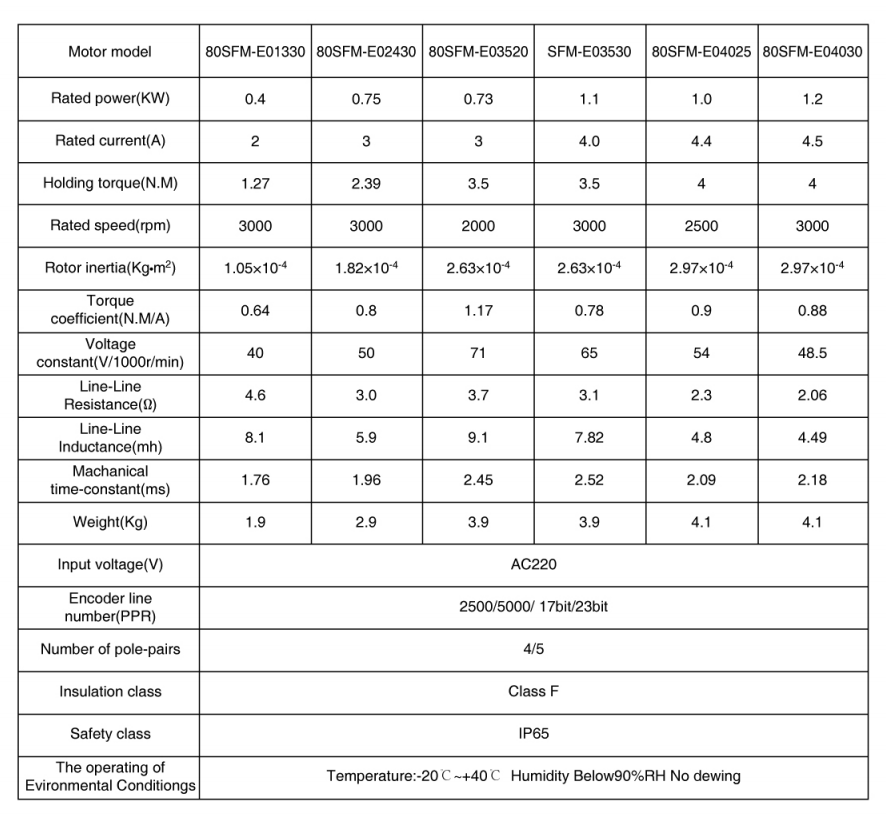

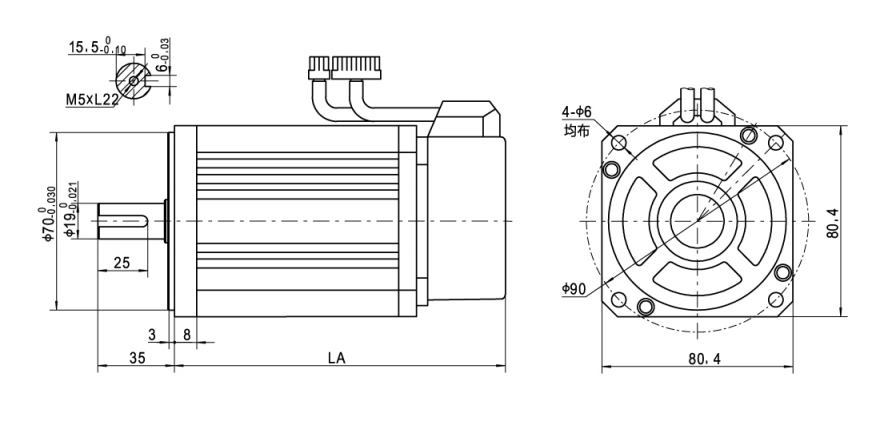

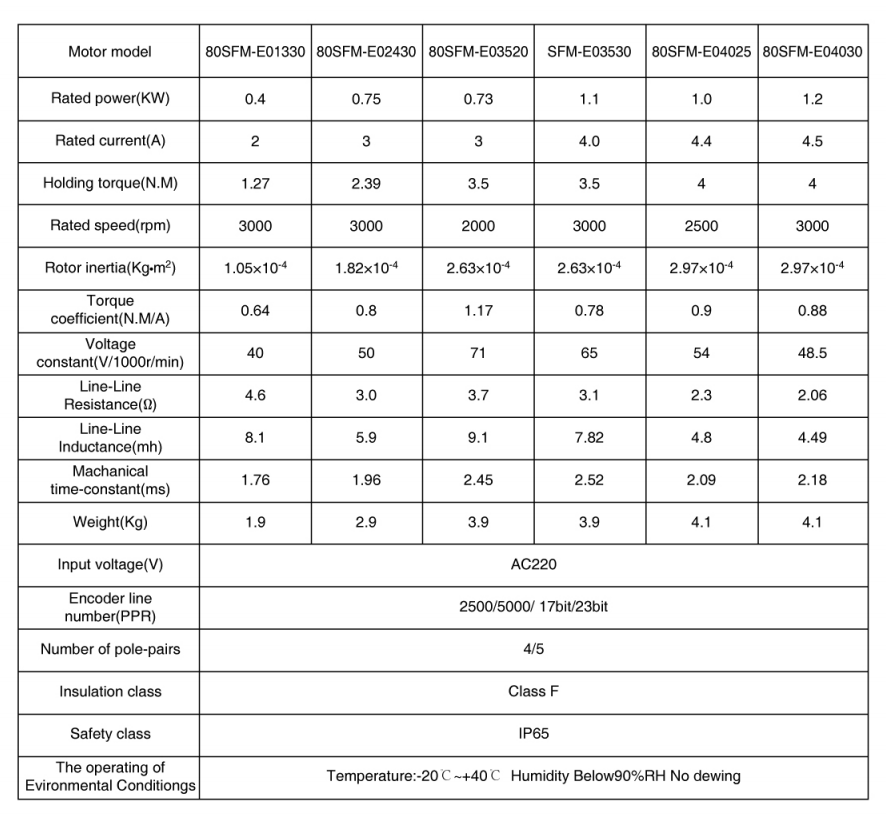

Series: 80 Series

Motor Type: PMSM (Permanent Magnet Synchronous Motor) / AC Servo

Voltage: 220 V AC, 3-phase, 50 / 60 Hz

Power Range: 100 W – 7.5 kW

Peak Torque: 0.6 Nm – 48 Nm

Speed Range: 500 – 6000 RPM

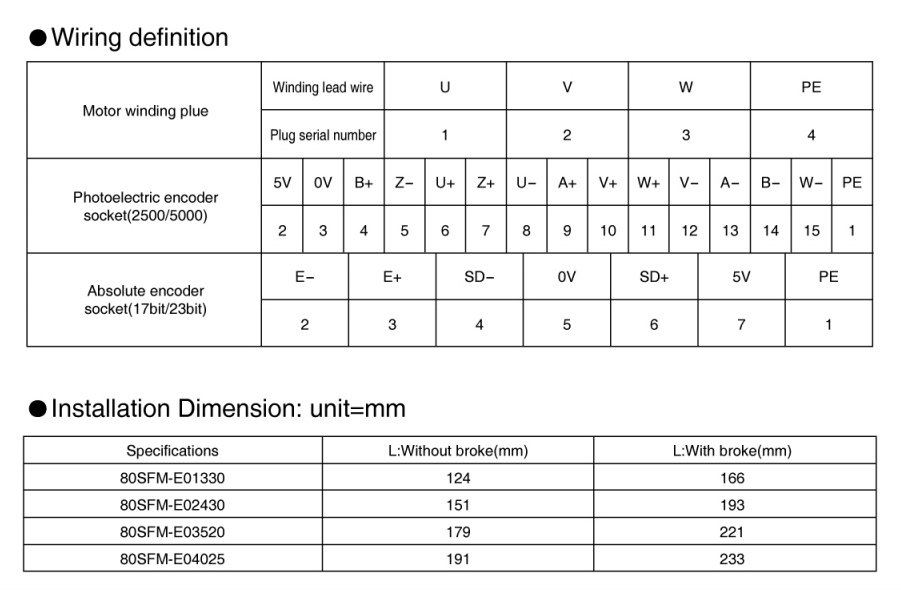

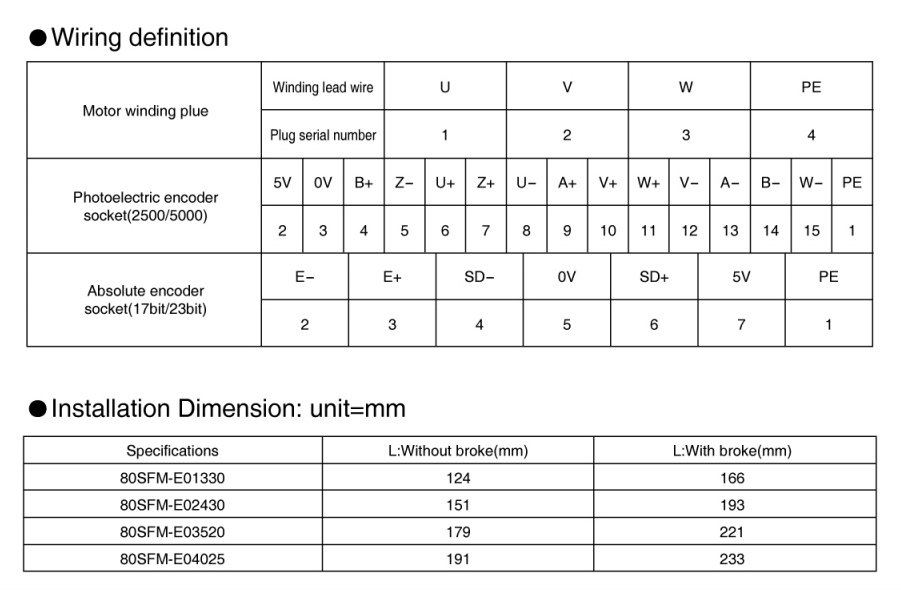

Encoder: 17-bit absolute (multi-turn optional)

Frame/Flange: 80 mm (compatible with NEMA 34 / 42)

Protection Class: IP65 (optional IP67)

Insulation Class: Class F (155 °C) standard

Communication Protocols: EtherCAT, CANopen, Modbus

Certifications: CE, UL, RoHS, ISO 9001

Options: Brake, coated shaft, custom cable, special mounting

High-precision machining tools & CNC systems

Robotic arms, pick-and-place systems, automated assembly

Servo presses and servo-driven manufacturing lines

Labeling, packaging and printing equipment

Upgrades or retrofit projects replacing legacy AC motors/servo systems

Engineered for precision — High-resolution encoder and quick response loop ensure accurate control and minimal overshoot.

Energy-efficient design — Meets IE4/IE5 standards, reducing operational cost and heat dissipation in confined spaces.

Flexible OEM/ODM capability — From shaft modifications to full drive integration, we support your custom requirements.

Global compatibility — Supports major automation protocols, complies with international standards, and integrates seamlessly into existing systems.

Reliable performance — IP65 protection, sturdy construction and long service life make it ideal for industrial conditions.

The Ritscher 80 Series is a high-efficiency AC servo motor designed specifically for industrial automation and motion control applications. With a compact 80 mm flange, 220 V three-phase power, and peak torque up to 48 Nm, this motor delivers exceptional performance for demanding environments. Equipped with a 17-bit absolute encoder and supporting EtherCAT, CANopen and Modbus communication protocols, the 80 Series ensures precise positioning, fast response, and seamless integration.

High Efficiency (IE4/IE5 level) — Optimised rotor design and low-loss winding reduce energy consumption and heat generation.

Wide Torque & Speed Range — From 0.6 Nm up to 48 Nm, speeds from 500 to 6000 RPM.

220 V 3-Phase Supply — Standard European/Asian industrial voltage for general-purpose installations.

17-bit Absolute Encoder (Standard) — Provides high-resolution feedback, eliminates homing cycle, supports multi-turn options.

Robust Protection & Compact Design — IP65 rated (IP67 optional), vibration resistance, NEMA34/42 compatible mounting.

Multi-Protocol Support — EtherCAT, CANopen, Modbus; Compatible with major drives (Yaskawa, Siemens, Delta, etc.).

Customisable Options — Brake, special shaft/coating, custom cable length, leading OEM/ODM support.

Industry Ready — Ideal for servo presses, CNC machines, robotic arms, labelling machines, pick-and-place equipment and other high-precision systems.

Series: 80 Series

Motor Type: PMSM (Permanent Magnet Synchronous Motor) / AC Servo

Voltage: 220 V AC, 3-phase, 50 / 60 Hz

Power Range: 100 W – 7.5 kW

Peak Torque: 0.6 Nm – 48 Nm

Speed Range: 500 – 6000 RPM

Encoder: 17-bit absolute (multi-turn optional)

Frame/Flange: 80 mm (compatible with NEMA 34 / 42)

Protection Class: IP65 (optional IP67)

Insulation Class: Class F (155 °C) standard

Communication Protocols: EtherCAT, CANopen, Modbus

Certifications: CE, UL, RoHS, ISO 9001

Options: Brake, coated shaft, custom cable, special mounting

High-precision machining tools & CNC systems

Robotic arms, pick-and-place systems, automated assembly

Servo presses and servo-driven manufacturing lines

Labeling, packaging and printing equipment

Upgrades or retrofit projects replacing legacy AC motors/servo systems

Engineered for precision — High-resolution encoder and quick response loop ensure accurate control and minimal overshoot.

Energy-efficient design — Meets IE4/IE5 standards, reducing operational cost and heat dissipation in confined spaces.

Flexible OEM/ODM capability — From shaft modifications to full drive integration, we support your custom requirements.

Global compatibility — Supports major automation protocols, complies with international standards, and integrates seamlessly into existing systems.

Reliable performance — IP65 protection, sturdy construction and long service life make it ideal for industrial conditions.