| Availability: | |

|---|---|

| Quantity: | |

Overview

This versatile DC Geared Motor is a compact, high-performance drive unit engineered for next-generation smart devices. Seamlessly integrating a reliable DC motor with a precision gearbox, it delivers the optimal balance of torque, speed, and control required for dynamic robotic movement, secure electromechanical actuation in smart locks, and smooth, responsive motion in premium consumer products. Its adaptable design makes it the ideal motion core for innovation across connected lifestyles.

Key Features & Advantages

Adaptable Torque & Speed Profiles: Available in a wide range of gear ratios and voltages, allowing precise tailoring of output characteristics—from high-torque, low-speed for lock bolt actuation to balanced speed-torque for robotic joints or automated mechanisms in consumer products.

Compact & Integrated Design: The combined motor-gearbox assembly minimizes footprint and simplifies integration into space-constrained designs such as robotic frames, lock bodies, and compact appliance housings.

Precise Control & Responsiveness: Excellent speed-torque linearity enables accurate control via simple PWM (Pulse Width Modulation), making it ideal for applications requiring repeatable positioning, such as a robotic arm’s range of motion or the exact extension/retraction of a lock bolt.

Quiet & Smooth Operation: Precision-machined gears and balanced motors ensure low acoustic noise and minimal vibration, enhancing user experience in smart home environments and sensitive applications.

High Reliability & Durability: Constructed with metal gears (brass/steel) and long-life bearings, designed for thousands of duty cycles. This ensures dependable operation for frequently used smart locks and durable performance in robotic applications.

Low Power Consumption: Optimized for battery or low-voltage DC power sources commonly used in portable robots, IoT locks, and USB-powered devices, extending operational life per charge.

Easy Integration & Customization: Available with multiple mounting options, shaft types (D-cut, pinion, smooth), and connector interfaces. Can be customized for specific voltage, RPM, and torque requirements.

Technical Specifications (Typical Ranges)

Motor Type: Permanent Magnet DC (PMDC) Geared Motor.

Voltage: 3V, 6V, 12V, 24V DC.

Output Speed: 10 to 500 RPM (customizable via gear ratio).

Output Torque: 0.5 Nm to 5 Nm+.

Gearbox Type: Planetary or spur gear.

Gear Material: Metal (steel/brass) for high torque and durability.

Shaft Options: Various diameters (3mm, 4mm, 6mm) with D-cut, flat, or pinion.

Protection: Standard IP20-IP42; sealed versions (IP54) available for dust/moisture resistance.

Application-Specific Benefits

For Robotics:

Provides precise joint actuation for robotic arms, wheels for mobile robots, and pan-tilt mechanisms.

Enables controlled movement with adequate torque to carry loads.

For Smart Locks:

Delivers high torque to reliably throw and retract deadbolts.

Supports silent, smooth operation for residential and commercial smart locks.

Compatible with battery-powered systems for wireless installation.

For Premium Consumer Products:

Enables automated motion in smart furniture (adjustable desks/lighting), high-end toys, automated dispensers, and interactive retail displays.

Enhances product value through smooth, quiet, and reliable automation.

Why Choose This DC Gear Motor?

Whether you’re building a agile robot, a secure smart lock, or an innovative connected product, this DC gear motor offers the perfect fusion of intelligence and motion. It transforms digital commands into precise physical action, enabling smarter, more responsive, and more engaging user experiences. Its reliability and adaptability make it the go-to drive solution for engineers and designers shaping the future of intelligent devices.

Note: Performance depends on correct voltage, load matching, and duty cycle. For battery-operated devices, consider stall current and gearbox efficiency to optimize battery life. Customization is available for specific application needs, including noise reduction, torque profiles, and shaft configurations.

Typical Applicaiton:

Housing Applicaiton

Power Tools

Electronic Lock

Medical Apparatus

| Gearbox Parameter | ||||||||

| Gearbox Length | L=9.1mm | |||||||

| Redcution Ratio | 1:10 | 1:30 | 1:50 | 1:70 | 1:100 | 1:150 | 1:210 | |

| 5V | Rated Torque(Kgf.cm) | 0.02 | 0.05 | 0.09 | 0.13 | 0.16 | 0.25 | 0.35 |

| Rated Speed(RPM) | 1140 | 400 | 228 | 161 | 114 | 76 | 54 | |

| 12V | Rated Torque(Kgf.cm) | 0.02 | 0.05 | 0.09 | 0.12 | 0.15 | 0.23 | 0.32 |

| Rated Speed(RPM) | 1230 | 400 | 246 | 178 | 125 | 83.3 | 75 | |

| Breaking Torque(Kgf.cm) | 0.25 | 0.5 | 0.9 | 1.25 | 1.5 | 2.5 | 3.5 | |

| Motor Parameter | ||||||||||

| MODEL | Voltage | No Load | Rated Load | Stall | ||||||

| Speed | Current | Speed | Current | Torque | Power | Eff | Torque | Current | ||

| V | Rpm | A | Rpm | A | gf.cm | W | % | gf.cm | A | |

| FF-N20-08262 | 5 | 8000 | 0.02 | 6202 | 0.072 | 3.51 | 0.12 | 64 | 24.8 | 0.25 |

| FF-N30-05455 | 12 | 15000 | 0.05 | 11150 | 0.15 | 2.62 | 0.22 | 68 | 11.5 | 0.5 |

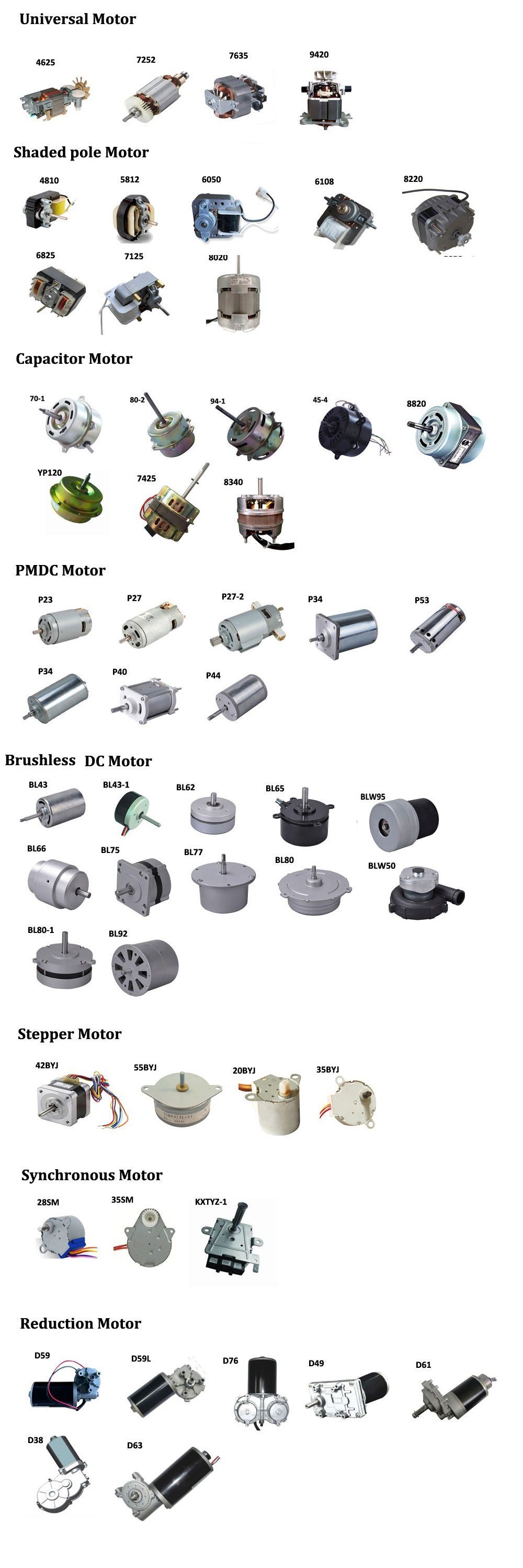

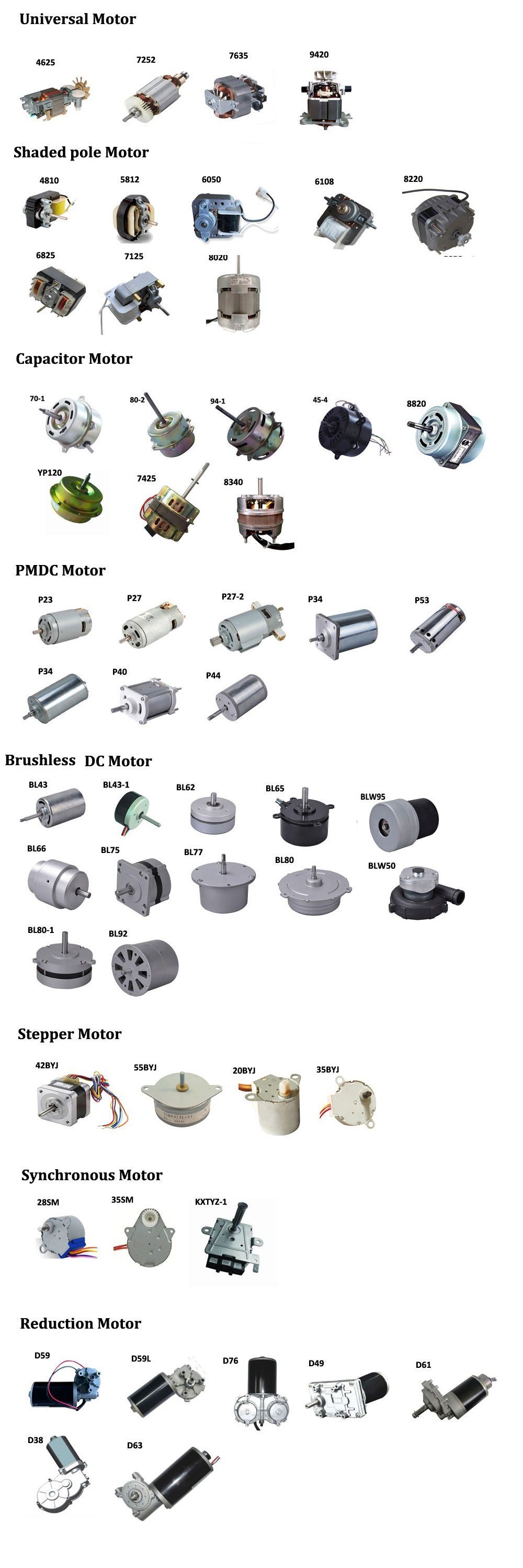

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.

Overview

This versatile DC Geared Motor is a compact, high-performance drive unit engineered for next-generation smart devices. Seamlessly integrating a reliable DC motor with a precision gearbox, it delivers the optimal balance of torque, speed, and control required for dynamic robotic movement, secure electromechanical actuation in smart locks, and smooth, responsive motion in premium consumer products. Its adaptable design makes it the ideal motion core for innovation across connected lifestyles.

Key Features & Advantages

Adaptable Torque & Speed Profiles: Available in a wide range of gear ratios and voltages, allowing precise tailoring of output characteristics—from high-torque, low-speed for lock bolt actuation to balanced speed-torque for robotic joints or automated mechanisms in consumer products.

Compact & Integrated Design: The combined motor-gearbox assembly minimizes footprint and simplifies integration into space-constrained designs such as robotic frames, lock bodies, and compact appliance housings.

Precise Control & Responsiveness: Excellent speed-torque linearity enables accurate control via simple PWM (Pulse Width Modulation), making it ideal for applications requiring repeatable positioning, such as a robotic arm’s range of motion or the exact extension/retraction of a lock bolt.

Quiet & Smooth Operation: Precision-machined gears and balanced motors ensure low acoustic noise and minimal vibration, enhancing user experience in smart home environments and sensitive applications.

High Reliability & Durability: Constructed with metal gears (brass/steel) and long-life bearings, designed for thousands of duty cycles. This ensures dependable operation for frequently used smart locks and durable performance in robotic applications.

Low Power Consumption: Optimized for battery or low-voltage DC power sources commonly used in portable robots, IoT locks, and USB-powered devices, extending operational life per charge.

Easy Integration & Customization: Available with multiple mounting options, shaft types (D-cut, pinion, smooth), and connector interfaces. Can be customized for specific voltage, RPM, and torque requirements.

Technical Specifications (Typical Ranges)

Motor Type: Permanent Magnet DC (PMDC) Geared Motor.

Voltage: 3V, 6V, 12V, 24V DC.

Output Speed: 10 to 500 RPM (customizable via gear ratio).

Output Torque: 0.5 Nm to 5 Nm+.

Gearbox Type: Planetary or spur gear.

Gear Material: Metal (steel/brass) for high torque and durability.

Shaft Options: Various diameters (3mm, 4mm, 6mm) with D-cut, flat, or pinion.

Protection: Standard IP20-IP42; sealed versions (IP54) available for dust/moisture resistance.

Application-Specific Benefits

For Robotics:

Provides precise joint actuation for robotic arms, wheels for mobile robots, and pan-tilt mechanisms.

Enables controlled movement with adequate torque to carry loads.

For Smart Locks:

Delivers high torque to reliably throw and retract deadbolts.

Supports silent, smooth operation for residential and commercial smart locks.

Compatible with battery-powered systems for wireless installation.

For Premium Consumer Products:

Enables automated motion in smart furniture (adjustable desks/lighting), high-end toys, automated dispensers, and interactive retail displays.

Enhances product value through smooth, quiet, and reliable automation.

Why Choose This DC Gear Motor?

Whether you’re building a agile robot, a secure smart lock, or an innovative connected product, this DC gear motor offers the perfect fusion of intelligence and motion. It transforms digital commands into precise physical action, enabling smarter, more responsive, and more engaging user experiences. Its reliability and adaptability make it the go-to drive solution for engineers and designers shaping the future of intelligent devices.

Note: Performance depends on correct voltage, load matching, and duty cycle. For battery-operated devices, consider stall current and gearbox efficiency to optimize battery life. Customization is available for specific application needs, including noise reduction, torque profiles, and shaft configurations.

Typical Applicaiton:

Housing Applicaiton

Power Tools

Electronic Lock

Medical Apparatus

| Gearbox Parameter | ||||||||

| Gearbox Length | L=9.1mm | |||||||

| Redcution Ratio | 1:10 | 1:30 | 1:50 | 1:70 | 1:100 | 1:150 | 1:210 | |

| 5V | Rated Torque(Kgf.cm) | 0.02 | 0.05 | 0.09 | 0.13 | 0.16 | 0.25 | 0.35 |

| Rated Speed(RPM) | 1140 | 400 | 228 | 161 | 114 | 76 | 54 | |

| 12V | Rated Torque(Kgf.cm) | 0.02 | 0.05 | 0.09 | 0.12 | 0.15 | 0.23 | 0.32 |

| Rated Speed(RPM) | 1230 | 400 | 246 | 178 | 125 | 83.3 | 75 | |

| Breaking Torque(Kgf.cm) | 0.25 | 0.5 | 0.9 | 1.25 | 1.5 | 2.5 | 3.5 | |

| Motor Parameter | ||||||||||

| MODEL | Voltage | No Load | Rated Load | Stall | ||||||

| Speed | Current | Speed | Current | Torque | Power | Eff | Torque | Current | ||

| V | Rpm | A | Rpm | A | gf.cm | W | % | gf.cm | A | |

| FF-N20-08262 | 5 | 8000 | 0.02 | 6202 | 0.072 | 3.51 | 0.12 | 64 | 24.8 | 0.25 |

| FF-N30-05455 | 12 | 15000 | 0.05 | 11150 | 0.15 | 2.62 | 0.22 | 68 | 11.5 | 0.5 |

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.