| Availability: | |

|---|---|

| Quantity: | |

U54

Ritscher

U54

The U54 Series is a compact, high-performance universal motor engineered to deliver the intense power and speed required by modern blending and mixing appliances. Designed to operate efficiently on both AC and DC power sources, this motor excels in high-speed, high-torque applications, making it the ideal drive solution for demanding kitchen tasks from crushing ice to kneading dense dough.

High Power & Speed in Compact Size: Delivers exceptionally high power density, achieving speeds up to 15,000 - 25,000 RPM (no-load) to generate the cutting and shearing force necessary for efficient blending, pureeing, and mixing.

High Starting & Running Torque: Provides instant, high torque at startup to overcome the initial inertia of heavy loads (e.g., frozen fruit, ice cubes, thick batter), ensuring smooth and consistent performance under variable load conditions.

Thermal & Durability-Optimized Design: Specifically built for the intermittent yet demanding duty cycles of kitchen appliances. Features high-temperature Class F or Class H insulation, robust commutators, high-grade carbon brushes, and enhanced cooling to ensure long service life despite frequent, high-load operation.

Speed Control Compatibility: Easily interfaces with simple user controls, such as multi-tap switches, rotary rheostats, or electronic triac-based speed controllers, allowing for variable speed settings from low (stirring) to high (pulverizing).

Low Noise & Vibration Engineering: Designed with precision-balanced armatures and optimized magnetic circuits to minimize operational noise and vibration, contributing to a more pleasant user experience and stable appliance operation.

Global Power Supply Compatibility: As a universal motor, it is designed to operate across a wide range of voltages (e.g., 120V~240V, 50/60 Hz), simplifying inventory and manufacturing for global markets.

Efficient Cooling & Ventilation: Incorporated with strategically designed air intakes and impellers to ensure effective heat dissipation during extended high-power operation, preventing overheating and maintaining performance.

Motor Type: Series-Wound Universal Motor (AC/DC).

Frame Size: U54 (Industry-standard compact appliance motor designation).

Input Power: AC 100-120V / 220-240V, 50/60 Hz.

Rated Power: Typically in the range of 300W to 1000W, matching the power needs of high-performance blenders and stand mixers.

No-Load Speed: Up to 20,000 RPM (varies by model and voltage).

Load Speed: Maintains high speed under typical blending loads.

Mounting: Standardized mounting studs or flanges for secure integration into appliance housing, often with anti-vibration dampeners.

Shaft: Precision-ground output shaft designed to securely couple with blade assemblies, gear drives, or planetary mixing attachments.

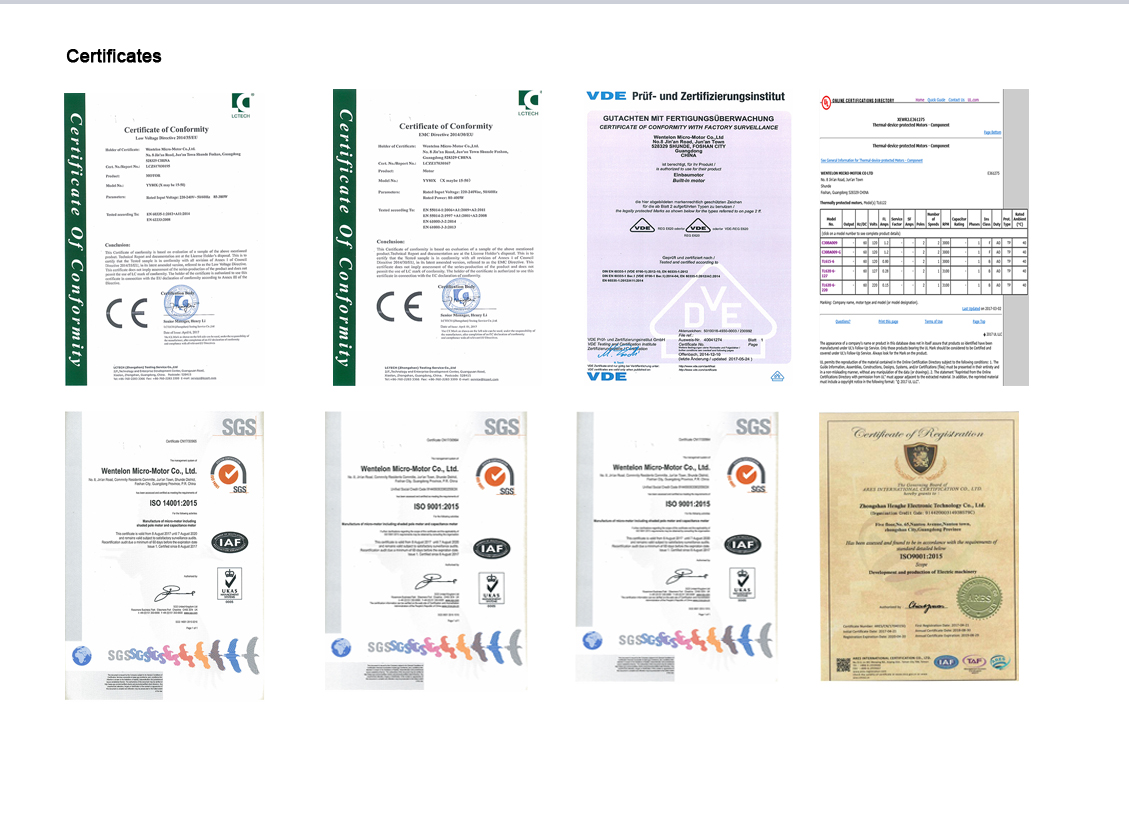

Safety & Compliance: Designed to meet key international appliance safety standards (e.g., UL, CE, IEC 60335).

This motor series is the driving force behind a wide range of high-performance food preparation appliances:

High-Speed Countertop Blenders

Food Processors & Chopper Attachments

Stand Mixers & Hand Mixers (high-power models)

Immersion (Stick) Blenders

Personal Smoothie Blenders

Grain Mills & Spice Grinders

For appliance manufacturers targeting the performance-driven segment of the market, the U54 Series offers the essential combination of brute power, compact size, and proven reliability. It is engineered to meet the rigorous demands of daily kitchen use, from quick pulses to extended mixing cycles. By providing consistent high-speed torque and durable construction, it enables the creation of blenders and mixers that deliver professional-grade results, building trust and satisfaction with every use.

Note: Motor performance in final application is influenced by blade design, jar geometry, and control system. Proper thermal management within the appliance housing is critical for optimal lifespan. Consult technical datasheets for specific performance curves, duty cycle ratings, and electrical specifications.

| Business Type: | Manufacturer | |

| Main Products: | Thermal Fuse,Thermostat,Shaded Pole Motor,Synchronous Motor,Ozone Generator | |

| Number Of Employees: | 101 - 200 People |

Trade & Market

| Main Markets: | Eastern Europe South America Western Europe North America Southeast Asia Mid East | |

| Total Annual Sales Volume: | Above US$100 Million | |

| Export Percentage: | 71% - 80% |

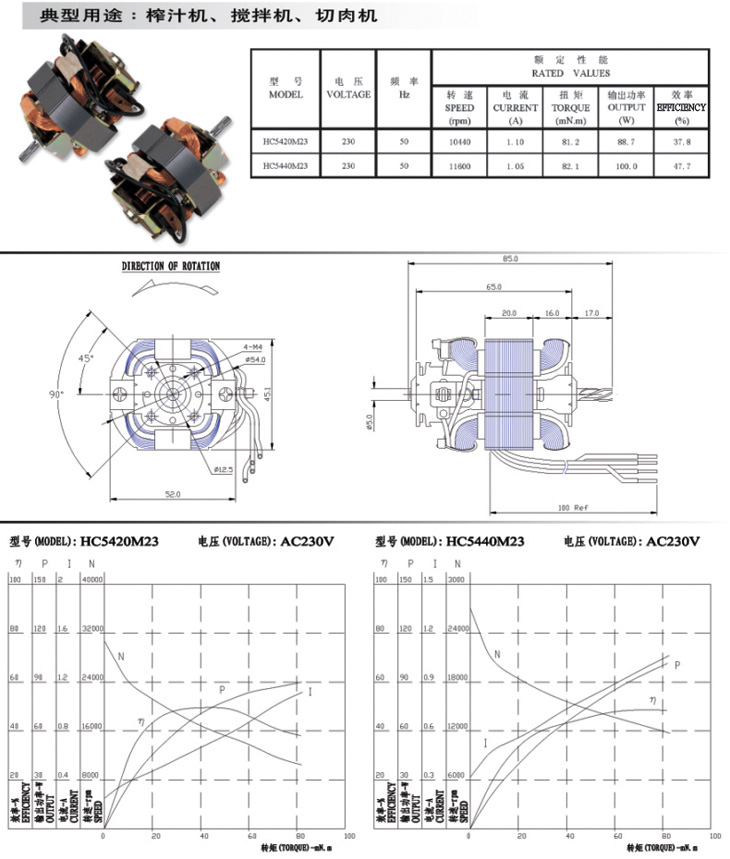

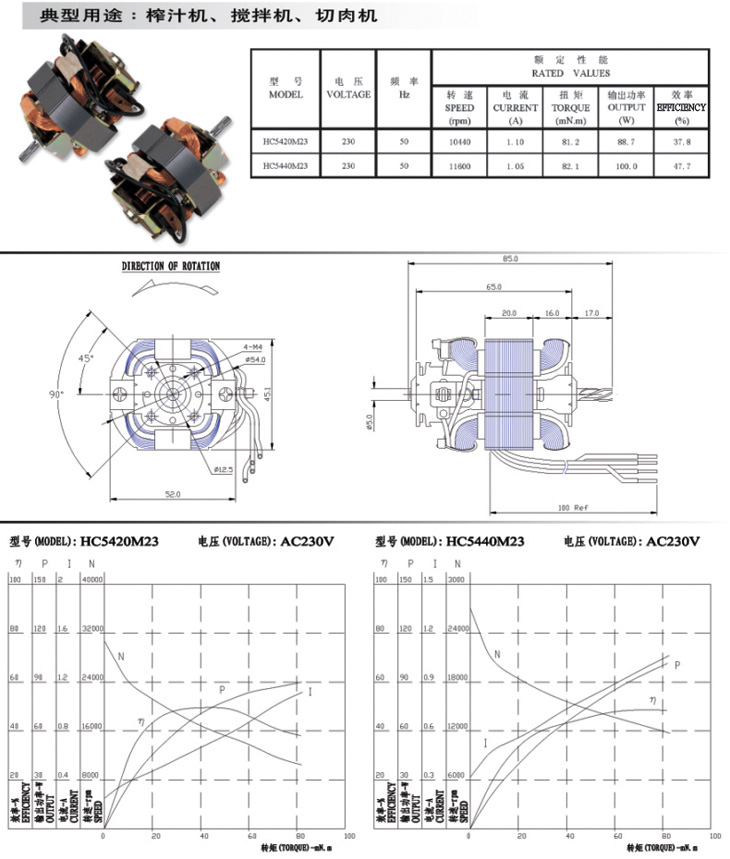

Mechanical dimensions

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.

The U54 Series is a compact, high-performance universal motor engineered to deliver the intense power and speed required by modern blending and mixing appliances. Designed to operate efficiently on both AC and DC power sources, this motor excels in high-speed, high-torque applications, making it the ideal drive solution for demanding kitchen tasks from crushing ice to kneading dense dough.

High Power & Speed in Compact Size: Delivers exceptionally high power density, achieving speeds up to 15,000 - 25,000 RPM (no-load) to generate the cutting and shearing force necessary for efficient blending, pureeing, and mixing.

High Starting & Running Torque: Provides instant, high torque at startup to overcome the initial inertia of heavy loads (e.g., frozen fruit, ice cubes, thick batter), ensuring smooth and consistent performance under variable load conditions.

Thermal & Durability-Optimized Design: Specifically built for the intermittent yet demanding duty cycles of kitchen appliances. Features high-temperature Class F or Class H insulation, robust commutators, high-grade carbon brushes, and enhanced cooling to ensure long service life despite frequent, high-load operation.

Speed Control Compatibility: Easily interfaces with simple user controls, such as multi-tap switches, rotary rheostats, or electronic triac-based speed controllers, allowing for variable speed settings from low (stirring) to high (pulverizing).

Low Noise & Vibration Engineering: Designed with precision-balanced armatures and optimized magnetic circuits to minimize operational noise and vibration, contributing to a more pleasant user experience and stable appliance operation.

Global Power Supply Compatibility: As a universal motor, it is designed to operate across a wide range of voltages (e.g., 120V~240V, 50/60 Hz), simplifying inventory and manufacturing for global markets.

Efficient Cooling & Ventilation: Incorporated with strategically designed air intakes and impellers to ensure effective heat dissipation during extended high-power operation, preventing overheating and maintaining performance.

Motor Type: Series-Wound Universal Motor (AC/DC).

Frame Size: U54 (Industry-standard compact appliance motor designation).

Input Power: AC 100-120V / 220-240V, 50/60 Hz.

Rated Power: Typically in the range of 300W to 1000W, matching the power needs of high-performance blenders and stand mixers.

No-Load Speed: Up to 20,000 RPM (varies by model and voltage).

Load Speed: Maintains high speed under typical blending loads.

Mounting: Standardized mounting studs or flanges for secure integration into appliance housing, often with anti-vibration dampeners.

Shaft: Precision-ground output shaft designed to securely couple with blade assemblies, gear drives, or planetary mixing attachments.

Safety & Compliance: Designed to meet key international appliance safety standards (e.g., UL, CE, IEC 60335).

This motor series is the driving force behind a wide range of high-performance food preparation appliances:

High-Speed Countertop Blenders

Food Processors & Chopper Attachments

Stand Mixers & Hand Mixers (high-power models)

Immersion (Stick) Blenders

Personal Smoothie Blenders

Grain Mills & Spice Grinders

For appliance manufacturers targeting the performance-driven segment of the market, the U54 Series offers the essential combination of brute power, compact size, and proven reliability. It is engineered to meet the rigorous demands of daily kitchen use, from quick pulses to extended mixing cycles. By providing consistent high-speed torque and durable construction, it enables the creation of blenders and mixers that deliver professional-grade results, building trust and satisfaction with every use.

Note: Motor performance in final application is influenced by blade design, jar geometry, and control system. Proper thermal management within the appliance housing is critical for optimal lifespan. Consult technical datasheets for specific performance curves, duty cycle ratings, and electrical specifications.

| Business Type: | Manufacturer | |

| Main Products: | Thermal Fuse,Thermostat,Shaded Pole Motor,Synchronous Motor,Ozone Generator | |

| Number Of Employees: | 101 - 200 People |

Trade & Market

| Main Markets: | Eastern Europe South America Western Europe North America Southeast Asia Mid East | |

| Total Annual Sales Volume: | Above US$100 Million | |

| Export Percentage: | 71% - 80% |

Mechanical dimensions

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

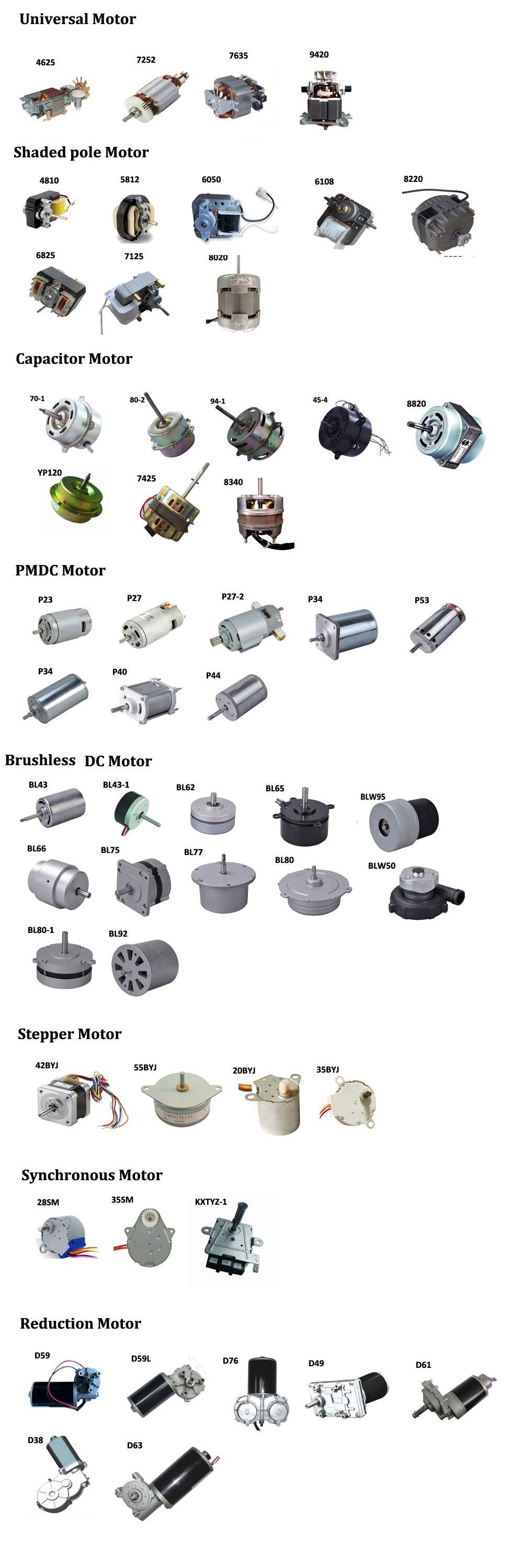

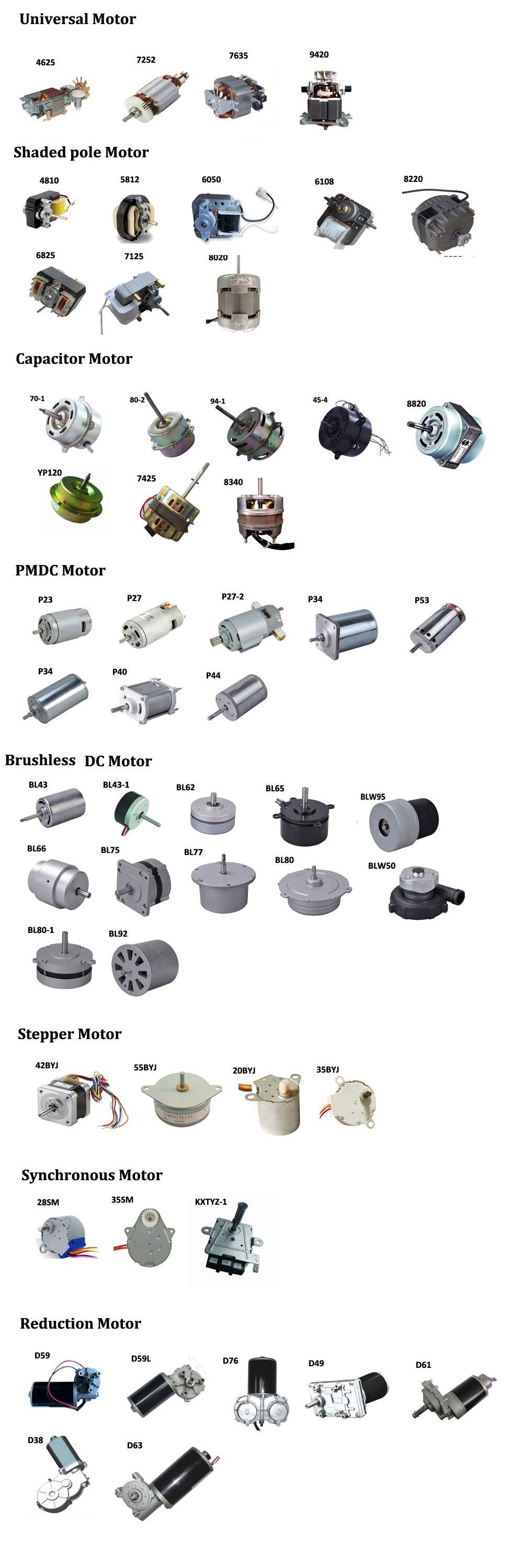

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,Hair Dryer Motor Blender Motor Mixer Motor,

Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement. But the less the better (like no more than 5pcs) on condition that the quantity is enough in case any changes needed after initial testing.