| Availability: | |

|---|---|

| Quantity: | |

YJ4808

Ritscher

Overview

The YJ4808B is a custom-engineered AC motor solution specifically designed to power the humidification systems within commercial and industrial bake ovens. This motor is tailored to meet the unique environmental and performance demands of high-temperature, high-humidity baking chambers, ensuring reliable and consistent steam or moisture generation for perfect crust development, oven spring, and baking consistency.

Key Features & Advantages

High-Temperature & Humidity Resilience: Specifically designed with high-temperature insulation (Class H or above), sealed bearings with high-temperature grease, and corrosion-resistant materials to withstand the continuous exposure to steam and ambient temperatures exceeding 100°C inside proofing and baking ovens.

Precise Vaporization Control: Engineered to provide stable torque and speed for driving water pumps, rotary atomizers, or fan assemblies that generate and distribute fine mist or steam. This ensures consistent and controllable humidity levels critical for various baking stages.

Food-Safe & Contaminant-Free Design: Constructed using materials and coatings that are non-toxic and resistant to corrosion from water and cleaning agents. The design minimizes the risk of lubricant or material contamination entering the humidification system.

Robust & Durable Construction: Built for 24/7 operation in commercial bakery environments. Features a robust housing (often aluminum or coated steel) and a sealed shaft to prevent moisture ingress into the motor windings, ensuring long-term reliability.

Low Maintenance & High Reliability: Utilizes a simple, robust induction motor design (often shaded pole or PSC type) with minimal failure points. Designed for easy access and serviceability within the oven's service panel to reduce downtime.

Quiet & Vibration-Free Operation: Precision-balanced to minimize noise and vibration, which is essential for maintaining a stable baking environment and preventing disturbance in the surrounding workspace.

Customized Integration: The "YJ4808B" designation indicates a customized build. Specifications such as shaft type (e.g., for direct pump coupling or fan mounting), mounting bracket, voltage (e.g., 120V/240V AC), and power are tailored to fit seamlessly into specific oven humidifier module designs.

Typical Custom Specifications

Motor Type: Single-Phase AC Motor (Shaded Pole or Permanent Split Capacitor - PSC).

Frame Reference: Custom 48mm frame size (indicative of compact design).

Input Power: 120V AC / 240V AC, 50/60 Hz, as per oven electrical system.

Output Power: Optimized for humidifier duty, typically in the range of 10W to 60W.

Output Configuration: Custom shaft (e.g., D-cut, threaded, or with impeller) for direct drive of a water pump impeller or a small centrifugal fan.

Protection: Totally Enclosed (TENV) or specially sealed construction to resist steam and flour dust.

Thermal Protection: Integrated thermal cut-off or overload protector as standard.

Application-Specific Role

This motor is the critical driver in oven humidification systems, enabling:

Steam Generation: Powering pumps that inject water into a steam generator or hot surface.

Mist Distribution: Driving fan assemblies that circulate and distribute atomized water mist evenly throughout the oven chamber.

Proofing Control: Maintaining precise humidity levels during the final proofing stage before baking.

Ideal For

Deck Ovens & Rack Ovens

Revolving/Traveling Tray Ovens

Commercial Convection Ovens with steam injection

Specialty Bread & Pastry Baking Lines

Why Choose the YJ4808B Customized Motor?

For commercial oven manufacturers, consistent humidity is non-negotiable for product quality. The YJ4808B is not an off-the-shelf component; it is a co-engineered solution built to survive and perform in one of the harshest environments in a bakery. Its customized design ensures a perfect fit and reliable operation, directly contributing to perfect oven spring, glossy crusts, and repeatable baking results. It represents a partnership in reliability for your high-value equipment.

Note: This is a custom-engineered component. All performance specifications, dimensions, and interface details are defined in collaboration with the oven manufacturer to meet the exact requirements of the humidification system. Refer to the oven's technical manual for specific service and replacement procedures.

Parameter

| Model | A of size | Shaft Dia | Volt | Power | Torque | Speed Rated |

| YJ4808 | 8mm | 4mm | 110-220V | 6W | 1.12mN.m | 3400RMP |

| YJ4810 | 10mm | 4mm | 110-220V | 10W | 3.42mN.m | 3000RMP |

| YJ4810 | 10mm | 5mm | 110-220V | 14W | 3.82mN.m | 3000RMP |

| YJ4815 | 15mm | 4mm | 110-220V | 11W | 7.97mN.m | 3400RMP |

This motor is engineered for durability and flexibility, making it ideal for manufacturers needing a custom AC motor solution for baking ovens, humidifiers, and other heat-resistant applications. Its low-maintenance design and reliable performance ensure long-term operation in demanding environments.

Interested in customization? Contact us for tailored specifications, including special voltages, shaft sizes, or additional safety certifications.

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

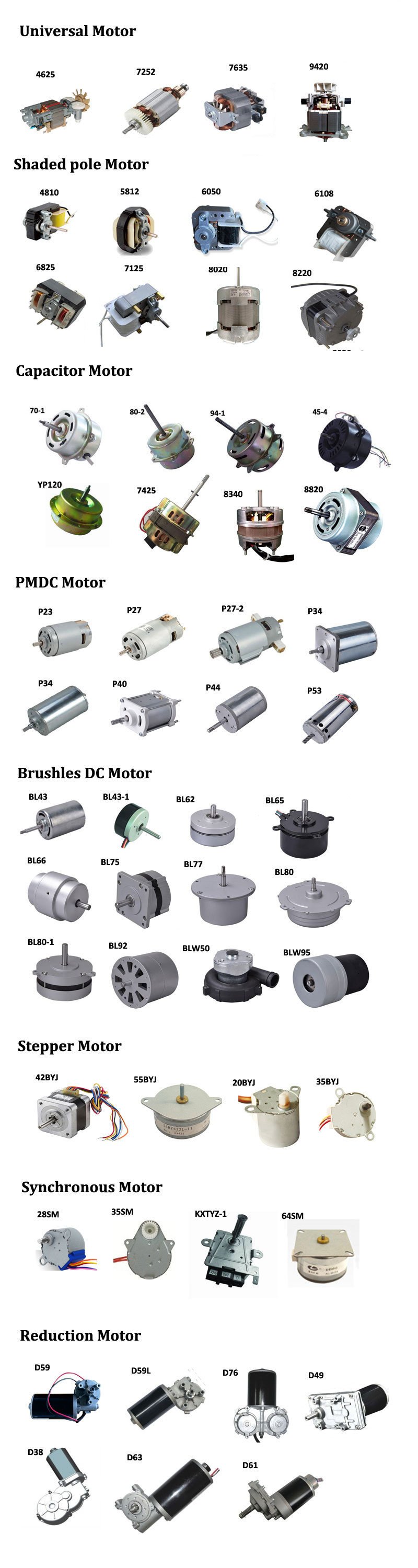

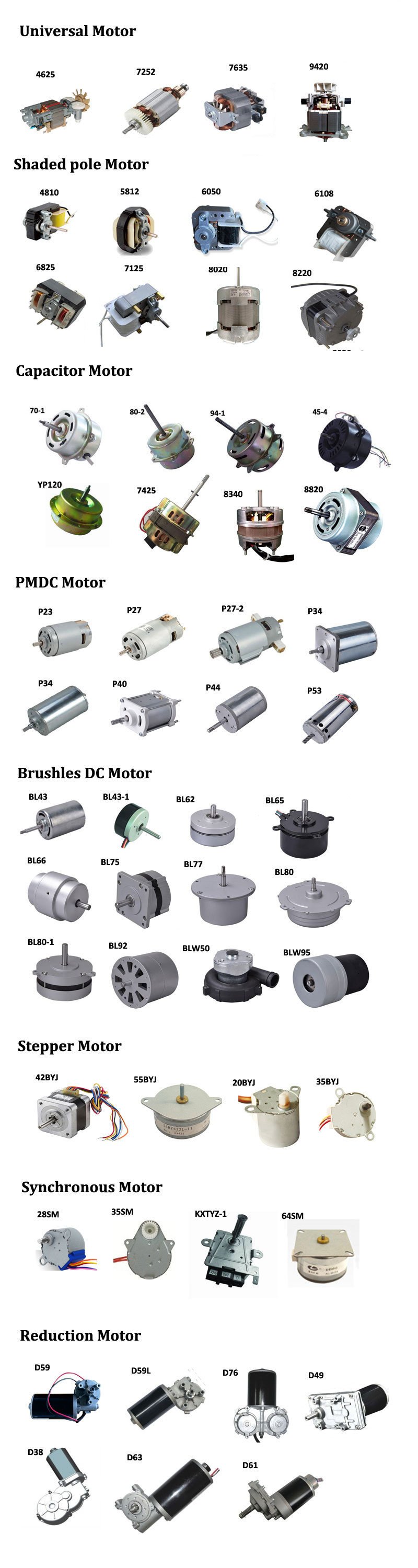

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,

Hair Dryer Motor Blender Motor Mixer Motor, Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,

Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement.

But the less the better (like no more than 5pcs) on condition that the quantity is enough in

case any changes needed after initial testing.

Overview

The YJ4808B is a custom-engineered AC motor solution specifically designed to power the humidification systems within commercial and industrial bake ovens. This motor is tailored to meet the unique environmental and performance demands of high-temperature, high-humidity baking chambers, ensuring reliable and consistent steam or moisture generation for perfect crust development, oven spring, and baking consistency.

Key Features & Advantages

High-Temperature & Humidity Resilience: Specifically designed with high-temperature insulation (Class H or above), sealed bearings with high-temperature grease, and corrosion-resistant materials to withstand the continuous exposure to steam and ambient temperatures exceeding 100°C inside proofing and baking ovens.

Precise Vaporization Control: Engineered to provide stable torque and speed for driving water pumps, rotary atomizers, or fan assemblies that generate and distribute fine mist or steam. This ensures consistent and controllable humidity levels critical for various baking stages.

Food-Safe & Contaminant-Free Design: Constructed using materials and coatings that are non-toxic and resistant to corrosion from water and cleaning agents. The design minimizes the risk of lubricant or material contamination entering the humidification system.

Robust & Durable Construction: Built for 24/7 operation in commercial bakery environments. Features a robust housing (often aluminum or coated steel) and a sealed shaft to prevent moisture ingress into the motor windings, ensuring long-term reliability.

Low Maintenance & High Reliability: Utilizes a simple, robust induction motor design (often shaded pole or PSC type) with minimal failure points. Designed for easy access and serviceability within the oven's service panel to reduce downtime.

Quiet & Vibration-Free Operation: Precision-balanced to minimize noise and vibration, which is essential for maintaining a stable baking environment and preventing disturbance in the surrounding workspace.

Customized Integration: The "YJ4808B" designation indicates a customized build. Specifications such as shaft type (e.g., for direct pump coupling or fan mounting), mounting bracket, voltage (e.g., 120V/240V AC), and power are tailored to fit seamlessly into specific oven humidifier module designs.

Typical Custom Specifications

Motor Type: Single-Phase AC Motor (Shaded Pole or Permanent Split Capacitor - PSC).

Frame Reference: Custom 48mm frame size (indicative of compact design).

Input Power: 120V AC / 240V AC, 50/60 Hz, as per oven electrical system.

Output Power: Optimized for humidifier duty, typically in the range of 10W to 60W.

Output Configuration: Custom shaft (e.g., D-cut, threaded, or with impeller) for direct drive of a water pump impeller or a small centrifugal fan.

Protection: Totally Enclosed (TENV) or specially sealed construction to resist steam and flour dust.

Thermal Protection: Integrated thermal cut-off or overload protector as standard.

Application-Specific Role

This motor is the critical driver in oven humidification systems, enabling:

Steam Generation: Powering pumps that inject water into a steam generator or hot surface.

Mist Distribution: Driving fan assemblies that circulate and distribute atomized water mist evenly throughout the oven chamber.

Proofing Control: Maintaining precise humidity levels during the final proofing stage before baking.

Ideal For

Deck Ovens & Rack Ovens

Revolving/Traveling Tray Ovens

Commercial Convection Ovens with steam injection

Specialty Bread & Pastry Baking Lines

Why Choose the YJ4808B Customized Motor?

For commercial oven manufacturers, consistent humidity is non-negotiable for product quality. The YJ4808B is not an off-the-shelf component; it is a co-engineered solution built to survive and perform in one of the harshest environments in a bakery. Its customized design ensures a perfect fit and reliable operation, directly contributing to perfect oven spring, glossy crusts, and repeatable baking results. It represents a partnership in reliability for your high-value equipment.

Note: This is a custom-engineered component. All performance specifications, dimensions, and interface details are defined in collaboration with the oven manufacturer to meet the exact requirements of the humidification system. Refer to the oven's technical manual for specific service and replacement procedures.

Parameter

| Model | A of size | Shaft Dia | Volt | Power | Torque | Speed Rated |

| YJ4808 | 8mm | 4mm | 110-220V | 6W | 1.12mN.m | 3400RMP |

| YJ4810 | 10mm | 4mm | 110-220V | 10W | 3.42mN.m | 3000RMP |

| YJ4810 | 10mm | 5mm | 110-220V | 14W | 3.82mN.m | 3000RMP |

| YJ4815 | 15mm | 4mm | 110-220V | 11W | 7.97mN.m | 3400RMP |

This motor is engineered for durability and flexibility, making it ideal for manufacturers needing a custom AC motor solution for baking ovens, humidifiers, and other heat-resistant applications. Its low-maintenance design and reliable performance ensure long-term operation in demanding environments.

Interested in customization? Contact us for tailored specifications, including special voltages, shaft sizes, or additional safety certifications.

ABOUT US

Ritscher group was set up in 2006.we always focus on micro-motors for household electrical appliance and industry appliance since setting up.currently we have two professional micro-motor factories in China which severally located in Ningbo city and Foshan city.it has an area of 25,000 square meters plants and more than 300 employees, annual output is 3 million pcs and has 5 million pcs annual producing capacity.after several years development,we had built a great reputation in the market and got more and more customers' trust in the world.

We started from shaded pole motors at beginning, up to now,our product included of shaded pole motors,synchronous motors,stepping motors ,capacitor motors, BLDC motors, DC motors and compressors. Our product are widely used for making refrigerators, freezers, micro-wave ovens, air warmers, air exhausters, ventilators,ovens, air filter, massage machines and many other equipments.

As a realiable quality guaranty,Ritscher has complete R&D departement,QC department,producing department,purchase department etc. has perfect producing equipment like Aluminum diecasting, Zinc diecasting, Sheet metal stamping, Plastic injection molding etc. also test/ detection device like multiplex temp measuring device, performance parameter inspection device, Phenol peptide solution pinhole tester,Anechoic room etc.

Endeavoring to provide the best product and service to customers,we always do the most effort to become an outstanding manufacturer of micro motors.

Ritscher is always willing to establish sincere business relationship with friends from all over the world.

Welcome contact with us!

Take ritscher ,enjoy modern life!

Our company FAQ for you

(1) Q: What kind motors you can provide?

A:For now,we mainly provide Kitchen Hood Motor,DC Motor,Gear Motor,Fan Motor Refrigerator Motor,

Hair Dryer Motor Blender Motor Mixer Motor, Shade Pole Motor,Capacitor Motor,BLDC Motor PMDC Motor,

Synchronous Motor,Stepping Motor etc.

(2) Q: Is it possible to visit your factory

A: Sure. But please kindly keep us posted a few days in advance. We need to check our

schedule to see if we are available then.

(3) Q: Can I get some samples

A: It depends. If only a few samples for personal use or replacement, I am afraid it will

be difficult for us to provide, because all of our motors are custom made and no stock

available if there is no further needs. If just sample testing before the official order and

our MOQ, price and other terms are acceptable, we'd love to provide samples.

(4) Q: Is there a MOQ for your motors?

A: Yes. The MOQ is between 1000~10,000pcs for different models after sample approval.

But it's also okay for us to accept smaller lots like a few dozens, hundreds or thousands

For the initial 3 orders after sample approval.For samples, there is no MOQ requirement.

But the less the better (like no more than 5pcs) on condition that the quantity is enough in

case any changes needed after initial testing.